|

|

|

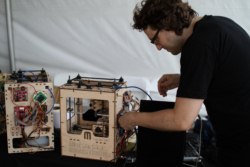

Report from the Maker Faire You may not be aware of this but something interesting has been going on. People are making things with their own hands again. And when I say "things" I mean an incredible variety of items ranging from super low tech ("crafts" and the like) all the way to the highest of high tech (custom integrated circuits, robotic devices, and much more). People who do this call themselves Makers and they are an interesting bunch indeed. This past weekend they gathered at the site of the 1964 World's Fair in Flushing Meadows for a two-day event called the Maker Faire, a strange combination of a geekfest, Burning Man, TED Conference, and medieval faire. Held in and around the New York Hall of Science, the event attracted thousands of inventors, builders, gadgeteers, performance artists, knitters, soap-makers, lock-pickers, welders, techno-hippies, and a vast assortment of people fascinated with it all. More about the Faire in a moment. Why is this Happening Now? All this is best illustrated by example, so I'm going to give you a bit of a walking tour of the Faire and show you some of the cool stuff that caught my eye. I suggest you start by clicking this link for a fast-moving 2-minute video overview. Note: All photos below may be enlarged in your browser by clicking on them. First stop was the large "Maker Bot" tent area. What is a Maker Bot you ask? At first glance, it looks like a big toy with gears and wires and motors, but on closer inspection you see that it's actually a mini-factory. A Maker Bot is a 3-D printer. It connects to your computer and will "print" an actual physical object -- almost as easily as your LaserJet prints out this month's TPS report. Except, instead of toner or ink, the Maker Bot constructs any small object (up to 4" x 4" x 6" in size) out of strong ABS plastic -- right before your eyes, without any human intervention. As you can tell, I get pretty jazzed over cool tech like this. But the Maker Faire is much more than a bunch of nerdly types and gear heads fawning over the latest and greatest techno-marvel. The event also attracts those who think differently and express themselves through various forms of functional art. Example: somebody constructed a 25-ton fully-operational life-size mousetrap game. A bunch of really-out-there folks from the "Madagascar Institute" built and operated several very dangerous carnival rides such as "Jet Ponies" (yes -- actually jet powered) and the 360 degree Swing of Death. What do you expect from an organization whose motto is "Fear is never Boring."

A musical group out of Austin Texas called Arc Attack brought a pair of 20' tall Tesla coils and performed in full chain mail from head to toe as ½ million volt lightning bolts hit their suits. I captured their finale on video and it is A MUST WATCH: Ozzy's Iron Man performed with a special-built all metal guitar. I've never experienced anything quite like it. A more participatory construction was the Axegrinder from Cyclecide, a 25-foot tall human-powered windmill that somehow produced music if you climbed up and pedaled it. (There was a long line of kids queued up for this).

Kids were also eager to take the controls of this knife wielding industrial robot and make it do some scary-looking Terminator-style moves. Luckily, the knife was made from soft plastic. Even so, and perhaps needless to say, there were far more dads than moms bringing their offspring to this area... On the somewhat more practical side, there were a number interesting and offbeat vehicles on display, including this wicked turbine powered mini-offroader.

Above is a scale model for ultra-cheap, hurricane and earthquake resistant permanent housing -- a modern interpretation of the Quonset hut. Full size, it's 10' by 16' but can be manufactured in a one car garage, shipped flat, and assembled on site in just a day. The machine cut marine plywood panels lock together securely using only a few nails and screws. An organization called Shelter 2.0, designed the shelters and makes the plans available for free under what's known as a "Creative Commons License," so that high school shop classes and other organizations can build these shelters for those in need. Shelter 2.0 also builds and sells the structures to commercial customers for $3850 but for every four shelters sold, will donate one to a family in need. Cool business model and I wish them all the best in this endeavor.

The highlight for me was Chris Anderson's opening session: "The Next Industrial Revolution." Anderson is editor-in-chief Wired (my hands-down favorite magazine) and author of ground-breaking books "The Long Tail: Why the Future of Business is Selling Less of More" and "Free: The Future of a Radical Price." He has a fascinating life story. His Swiss grandfather invented and patented the first automatic lawn sprinkler. Anderson spent his boyhood summers in grandfather's workshop, learning how to build things from scratch -- starting with a raw block of metal -- using a lathe and other machine tools. No wonder he has become one of the leading proponents of Maker culture. Today, the heavy lifting of metalwork can be automated and/or outsourced. Technology advances over the last two decades -- enabled first by cheap and ubiquitous personal computers and the always-on web, and then by social networks and remote collaboration -- have set the stage for the next great leap forward. The past emphasis has been on creating, managing, transmitting, and accessing information. Data. Bits. Now, the common availability of cheap 3D printers and other automated "personal" manufacturing devices has enabled thousands of new microbusinesses, selling unique goods on Etsy, and providing the marketplace with what the mega corporations and big box retailers can't. Anderson said, "The past decade was about finding new social and innovation models on the web. The next decade will be about applying them to the real world." This is a trend to watch.

Next stop was the ShopBot tent, where big CNC (computer controlled) woodworking tools were being demonstrated. You can see one in operation on my quick video walkthrough (link at beginning of this article). It's mesmerizing to watch a ShopBot tool create "something from a block of nothing."

My final stop was with the nice folks at Shapeways, a Netherlands-based global mini manufacturer now setting up operations in the States. Shapeways is a manufacturing service bureau. They have the most advanced 3D printing technologies and can take your uploaded files, turn them into custom metal objects, and ship them anywhere in the world that UPS serves within 2 weeks. Shapeways also maintains a huge gallery of products for sale, many of which can be customized. A number of these were displayed at the Faire. Here I'm holding a really intriguing art piece that could not be easily manufactured by conventional means, but was just a button-push for a 3D printer. That's a wrap for Maker Faire 2010. This was the first time the event was held in New York. It started in 2006 in California and the Bay Area Faire now attracts over 60,000 people. I have no doubt future East Coast Faires will become equally popular. I'll be back for sure.

|